In the rapidly evolving landscape of mining technology, the integration of mining intelligence track enclosures has become essential for optimizing data collection and analysis. Did you know that effective data management can enhance operational efficiency by up to 30%? This article delves into how these specialized aluminum enclosures contribute to improved data handling, ensuring that mining operations are not only efficient but also sustainable.

Understanding Mining Intelligence Track Enclosures

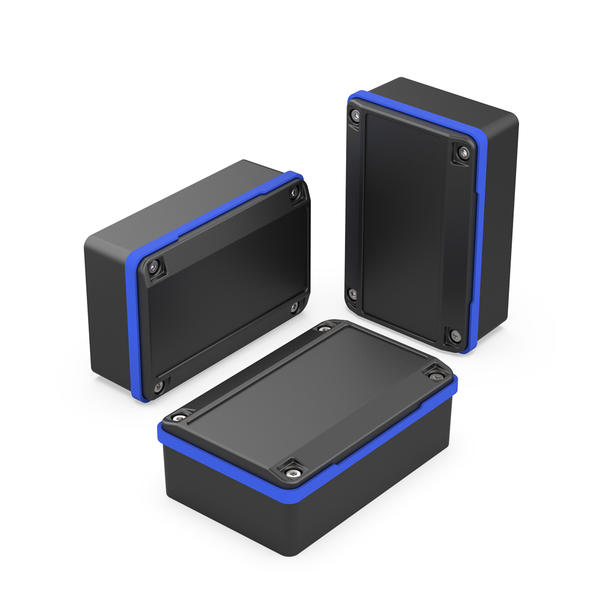

Mining intelligence track enclosures are robust, protective casings designed to house sensitive electronic equipment utilized in mining operations. These enclosures safeguard devices from harsh environmental conditions, ensuring uninterrupted data collection and analysis.

Durability: Constructed from high-quality aluminum, these enclosures resist corrosion, impact, and wear over time. This durability is crucial in mining environments where equipment is exposed to dust, moisture, and extreme temperatures.

Temperature Control: Effective thermal management systems integrated into these enclosures prevent overheating of sensitive electronic components. Features such as ventilation grilles or heat sinks help dissipate heat, ensuring optimal operating conditions.

Customizability: Tailored designs allow for specific operational needs to be met. Whether it’s accommodating various sensors or communication devices, these enclosures can be customized in size, shape, and internal layout.

The Importance of Data Collection in Mining

Performance Monitoring: Real-time data allows operators to track equipment performance metrics such as usage hours, load conditions, and operational efficiency. This information is vital for identifying trends and making informed decisions about maintenance schedules.

Safety Enhancements: Continuous monitoring of environmental conditions—such as gas levels, temperature fluctuations, and structural integrity—ensures worker safety. Data collected from sensors can trigger alarms or alerts when hazardous conditions arise.

Resource Management: Accurate data aids in optimizing resource allocation by providing insights into material usage patterns and waste production. This leads to more efficient operations and reduced costs.

How Mining Intelligence Track Enclosures Enhance Data Collection

1. Protection from Environmental Factors

Mining sites often expose equipment to extreme weather conditions, dust, and moisture. Mining intelligence track enclosures provide essential protection through:

- Waterproofing: Many models feature IP-rated designs that ensure protection against water ingress. This is particularly important in areas prone to heavy rainfall or flooding.

- Dust Resistance: Enclosures are designed with seals and gaskets that prevent dust accumulation inside. This protection is critical in maintaining the functionality of sensitive electronics over time.

2. Improved Signal Integrity

The effectiveness of data transmission relies heavily on the integrity of signals. These enclosures are designed to minimize electromagnetic interference (EMI) through:

- Shielding Techniques: Many enclosures incorporate materials that absorb or deflect EMI, ensuring that devices operate without disruption from external signals.

- Data Accuracy: Clean signals lead to more accurate data collection. Enhanced signal integrity supports continuous communication between devices and central systems, reducing the likelihood of data loss or corruption.

3. Enhanced Customization Options

With the ability to customize aluminum enclosures, mining companies can:

- Tailor Designs: Accommodate specific sensors and devices needed for various applications such as environmental monitoring or equipment diagnostics. Customization options may include cutouts for cables or mounting brackets for additional hardware.

- Integrate Advanced Features: Include ventilation systems or additional ports for easier connectivity with other devices. This flexibility allows companies to adapt their setups as technology evolves.

Real-world Applications

To illustrate the effectiveness of mining intelligence track enclosures, consider a case study from a leading mining operation in Australia:

By implementing custom aluminum enclosures for their data collection devices, they achieved a 25% increase in data accuracy, which led to better decision-making processes regarding resource allocation and equipment usage.

Additionally, they experienced a reduction in equipment downtime by 15%, thanks to proactive maintenance alerts generated by real-time monitoring systems housed within these enclosures.

This case exemplifies how investing in quality enclosures can yield significant operational benefits.

Optimizing Your Mining Operations with Aluminum Enclosures

Investing in quality aluminum enclosures is not just about protection; it’s about enhancing overall operational efficiency. Here’s how you can optimize your mining operations:

- Choose the Right Specifications: Assess your specific environmental and operational requirements before selecting an enclosure. Consider factors such as size constraints, exposure risks (e.g., moisture or dust), and thermal management needs.

- Regular Maintenance Checks: Periodically inspect the integrity of your enclosures for signs of wear or damage. Regular maintenance helps prevent potential issues before they escalate into costly repairs or downtime.

- Leverage Custom Solutions: Collaborate with manufacturers who offer tailored designs that meet your unique needs. Custom solutions ensure that your equipment operates optimally within its protective casing.

Conclusion

Mining intelligence track enclosures play a pivotal role in enhancing data collection and analysis within the mining sector. By providing robust protection against environmental factors while ensuring signal integrity and customization options, these aluminum enclosures empower mining companies to optimize their operations effectively.

Investing in high-quality aluminum enclosures not only safeguards your equipment but also drives efficiency, safety, and sustainability in your mining operations. For tailored solutions that meet your specific needs, consider partnering with a professional aluminum enclosure manufacturer.