When selecting the perfect electronics enclosure box for your project, one of the most important decisions you'll face is choosing the right material. Your choice can significantly impact the durability, performance, and protection of your electronics, whether you're working on industrial automation, consumer electronics, or a custom design solution. But how do you decide between a metal enclosure and a plastic one?

In this article, we'll explore the benefits and drawbacks of both aluminum electronics enclosure boxes and plastic enclosures. We will help you make an informed decision based on factors like strength, durability, environmental protection, and cost.

Understanding Electronics Enclosure Boxes

An electronics enclosure box is designed to protect sensitive electronic components from environmental hazards such as dust, water, heat, and electromagnetic interference (EMI). Whether you're safeguarding components in a consumer product or ensuring reliability in harsh industrial environments, the right material for the enclosure plays a crucial role in the long-term performance of your electronics.

Aluminum enclosures and plastic enclosures are the two most common materials, each with distinct advantages. Let's dive into the comparison between these materials to help you choose the best solution for your needs.

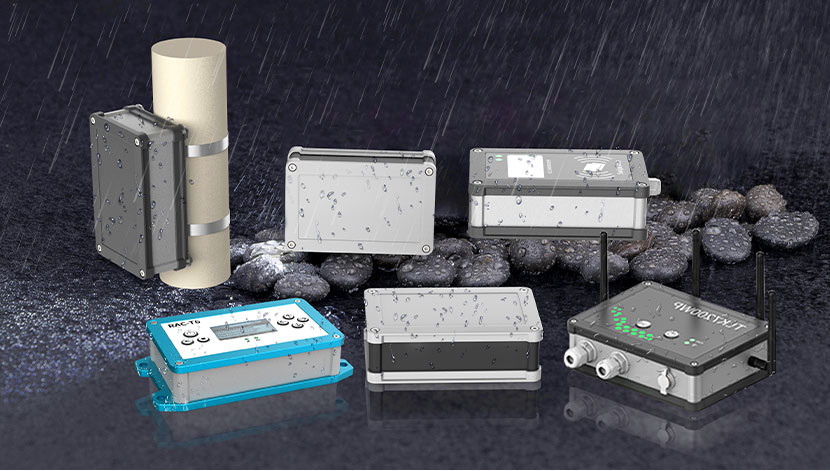

IP68 Waterproof Aluminum enclosure

Aluminum Enclosure Box: Strength and Durability

Aluminum electronics enclosure boxes are known for their excellent strength-to-weight ratio. This material offers superior protection against impact and corrosion, making it an ideal choice for applications requiring high durability. Some key benefits of aluminum enclosures include:

Durability: Aluminum enclosures provide enhanced resistance to physical damage and wear, making them suitable for use in demanding environments.

Heat Dissipation: Aluminum is an excellent conductor of heat, which helps dissipate heat generated by internal electronics, reducing the risk of overheating and prolonging the lifespan of the components.

Electromagnetic Shielding: One of the key advantages of aluminum is its ability to provide effective EMI shielding. This feature is essential for electronics that may be exposed to electromagnetic interference, ensuring uninterrupted operation.

Corrosion Resistance: Aluminum is naturally resistant to corrosion, especially when treated with protective coatings, making it ideal for outdoor and marine applications.

However, aluminum enclosures also have some disadvantages, such as being more expensive than plastic options and requiring additional manufacturing processes like cutting or welding.

Plastic Enclosure Box: Cost-Effectiveness and Versatility

Plastic electronics enclosure boxes are popular for their versatility and cost-effectiveness. They are lightweight, easy to manufacture, and offer a wide range of design possibilities. Key benefits of plastic enclosures include:

Lightweight: Plastic enclosures are significantly lighter than aluminum, which can be beneficial in portable applications or where weight is a critical factor.

Cost-Effective: Plastic is generally cheaper to produce, especially in large quantities, making it an attractive option for cost-sensitive projects.

Design Flexibility: Plastic enclosures can be molded into a variety of shapes, offering more design flexibility compared to metal enclosures.

Electrical Insulation: Plastic enclosures are non-conductive, meaning they provide inherent electrical insulation, which can be advantageous for certain applications.

On the downside, plastic enclosures are not as durable as aluminum ones. They can crack under impact, and they don't offer the same level of heat dissipation or EMI shielding. Additionally, they may degrade when exposed to UV radiation over time, making them less suitable for outdoor use unless specially treated.

Factors to Consider When Choosing Between Metal and Plastic Enclosures

When deciding between aluminum and plastic electronics enclosure boxes, consider the following factors:

1. Application Environment

If your electronics will be exposed to harsh conditions such as extreme temperatures, high humidity, or strong impacts, an aluminum enclosure box may be the better choice due to its superior durability and corrosion resistance. On the other hand, if your application is in a controlled indoor environment where the enclosure won't be subjected to extreme conditions, a plastic enclosure may suffice.

waterproof electronics enclosure box

2. Thermal Management

For applications that generate significant amounts of heat, aluminum is the better option due to its ability to dissipate heat efficiently. Plastic enclosures, while effective in many cases, may require additional cooling mechanisms to prevent overheating.

3. Electromagnetic Interference (EMI) Protection

If your electronics need protection from electromagnetic interference, an aluminum enclosure box is essential. Aluminum acts as a natural shield against EMI, which is particularly important for sensitive electronics like communication devices and industrial control systems.

4. Cost and Production Volume

For projects with tight budgets or large production runs, plastic enclosures are typically more cost-effective due to their lower manufacturing costs and flexibility in mass production. However, if your project demands higher performance and long-term reliability, the extra investment in aluminum enclosures may be worth it.

Conclusion

The choice between an aluminum electronics enclosure box and a plastic one ultimately depends on your specific needs. If you require durability, heat dissipation, and EMI shielding, aluminum enclosures are the best option. However, if cost, lightweight design, and electrical insulation are your primary concerns, plastic enclosures may be the better choice.

At YONGU, we specialize in custom aluminum electronics enclosure solutions tailored to meet your specific requirements. Whether you need enhanced durability, superior heat management, or protection against EMI, our aluminum enclosures provide the performance and reliability you need. Explore our range of aluminum enclosures to find the perfect solution for your next project!